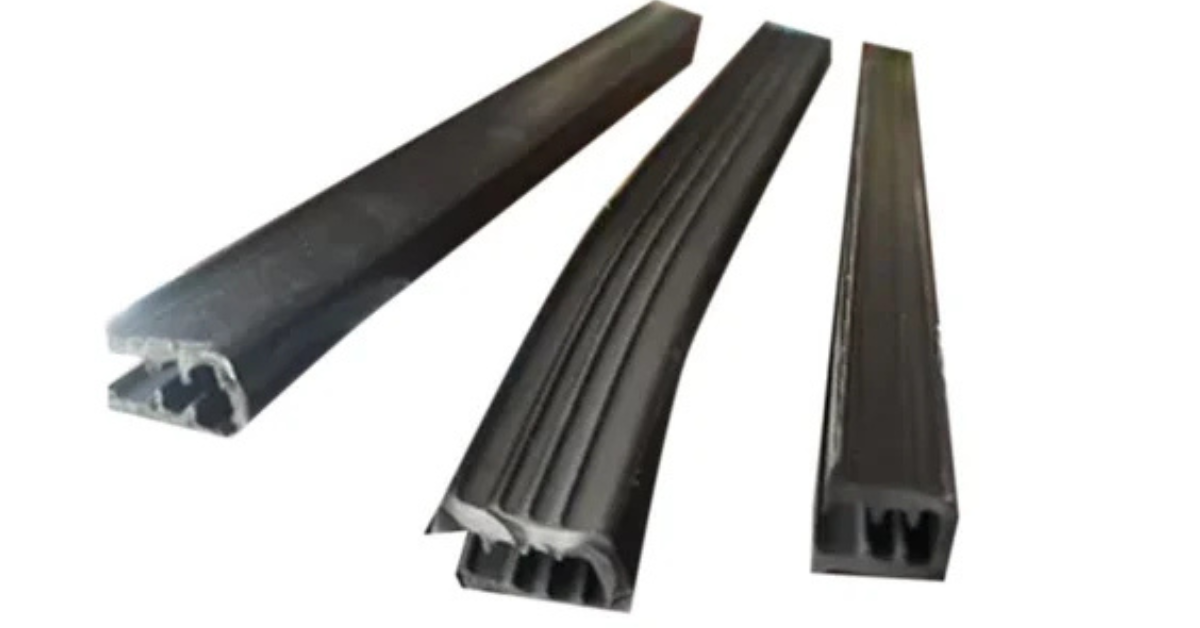

In the ever-evolving world of transportation, innovations are key to ensuring safety and efficiency. Enter nu van tech 53 ft rubber seal with their groundbreaking 53 ft rubber seal technology. This cutting-edge solution has transformed how goods are transported, providing unmatched durability and reliability. Whether you’re shipping fragile items or bulk materials, this advanced sealing method promises to revolutionize your logistics operations. Join us as we explore what makes the Nu Van Tech 53 ft rubber seal a game-changer in the industry and discover its far-reaching benefits for businesses everywhere.

Advantages of using this technology for transportation

The Nu Van Tech 53 ft rubber seal technology brings a fresh approach to transportation. Its design offers unparalleled flexibility, adapting seamlessly to various cargo types.

One of the standout advantages is its ability to create an airtight seal. This significantly reduces the risk of contamination during transit, preserving product integrity and quality.

Moreover, the lightweight nature of the rubber seal enhances fuel efficiency. Companies can transport goods without adding unnecessary weight, leading to lower operational costs.

Durability plays a crucial role as well. The robust construction withstands harsh conditions, reducing maintenance needs and prolonging service life.

Additionally, installation is straightforward and quick. This minimizes downtime when integrating into existing systems—an essential factor for busy logistics operations.

With these benefits combined, it’s clear that embracing this advanced sealing technology transforms how businesses approach their transportation challenges.

How it compares to traditional methods of sealing

Nu Van Tech’s 53 ft rubber seal technology stands out when compared to traditional sealing methods. Classic options often rely on multiple smaller seals or adhesives, making installation cumbersome and time-consuming.

The continuous design of the Nu Van Tech seal eliminates joints. This reduces potential leak points significantly, enhancing overall reliability. Traditional methods may require regular maintenance to address wear and tear; however, the durability of this innovative rubber seal minimizes that need.

Furthermore, conventional sealing solutions can struggle with varying temperatures and environmental conditions. The advanced materials used in Nu Van Tech’s product provide superior resilience against such challenges.

Companies using older methods might experience increased downtime during repairs or replacements. In contrast, the efficiency introduced by Nu Van Tech’s technology allows for smoother operations without frequent interruptions.

Cost-effectiveness and efficiency of Nu Van Tech’s 53 ft rubber seal

Nu Van Tech’s 53 ft rubber seal stands out not only for its superior sealing capabilities but also for its impressive cost-effectiveness. Businesses can expect to see significant savings in maintenance and repair costs over time. The durable material is engineered to withstand harsh conditions, reducing the need for frequent replacements.

Efficiency shines through in the installation process as well. The seamless design minimizes labor hours, allowing teams to focus on other essential tasks. This translates into quicker turnaround times and enhanced productivity.

Moreover, companies using this technology report fewer incidents related to leaks or damages during transport. Fewer disruptions mean that logistics operations run smoothly, ultimately improving overall profitability.

With energy efficiency becoming increasingly important, Nu Van Tech’s seals help protect goods from temperature fluctuations as well. This additional layer of protection leads to less spoilage and waste—a win-win situation for both businesses and the environment.

Case studies and success stories of companies who have implemented this technology

Several companies have experienced remarkable success after adopting Nu Van Tech’s 53 ft rubber seal technology. One notable case is a logistics provider that faced challenges with moisture and dust contamination during transport.

After implementing the rubber seal, they reported a significant reduction in damage to goods. Their customer satisfaction ratings increased as clients noticed fewer complaints about product integrity.

Another example involves a manufacturer of temperature-sensitive products. By utilizing this sealing technology, they maintained optimal conditions throughout the shipping process. This led to improved shelf life for their products and reduced waste.

A food distribution company also benefited greatly from this innovation. They found that the seals minimized spoilage during transit, allowing them to deliver fresher produce to retailers consistently.

These stories highlight how diverse industries can tap into Nu Van Tech’s expertise for tangible improvements in operational efficiency and product quality.

Potential industries that can benefit from this technology

The Nu Van Tech 53 ft rubber seal technology opens doors across various industries.

Transportation and logistics can greatly benefit from enhanced sealing solutions. This technology minimizes leaks and ensures cargo integrity during transit.

In the food industry, maintaining freshness is crucial. The advanced sealing capabilities help reduce spoilage and extend shelf life, ensuring products reach consumers in pristine condition.

Construction companies also stand to gain. Improved seals can enhance energy efficiency by preventing air leaks in buildings, leading to cost savings on heating and cooling.

Additionally, pharmaceutical firms require strict contamination controls. The reliability of the Nu Van Tech rubber seal supports compliance with health regulations while protecting sensitive materials.

Automotive manufacturers can leverage this technology for improved durability in vehicle components, enhancing performance over time without compromising safety or quality.

Future developments and advancements in Nu Van Tech’s rubber seal technology

The landscape of rubber seal technology is evolving rapidly. Nu Van Tech is at the forefront, continuously innovating its 53 ft rubber seal offerings. Future developments may include enhanced materials that provide even better durability and flexibility.

Research into eco-friendly compounds could lead to seals that not only perform well but also contribute to sustainability efforts. Imagine a product that reduces environmental impact while maintaining high performance.

Advanced manufacturing techniques might also play a role in creating customized solutions for different industries. Tailored seals could meet specific needs, leading to improved efficiency across various applications.

Additionally, smart technology integration could be on the horizon. Incorporating sensors into rubber seals would allow real-time monitoring of conditions like pressure and temperature, enabling more proactive maintenance strategies. These advancements promise not just improvements in functionality but also potential cost savings for businesses adapting to new technologies.

Conclusion: Why

Nu Van Tech has emerged as a leader in innovative sealing solutions with its 53 ft rubber seal technology. This advancement offers significant advantages for the transportation sector, making it easier to achieve efficient and effective sealing for various applications.

The comparisons drawn between this modern sealing technology and traditional methods highlight a clear shift towards better performance and reliability. Businesses are already reaping the benefits of enhanced cost-effectiveness, boosting their operational efficiency while minimizing maintenance costs.

Real-world case studies showcase how companies have successfully implemented Nu Van Tech’s 53 ft rubber seal, leading to improved safety standards and reduced product loss during transit. Industries such as logistics, manufacturing, and construction stand to gain immensely from integrating this cutting-edge solution into their operations.

Looking ahead, there is immense potential for further developments in Nu Van Tech’s rubber seal technology. As industries evolve and demands grow more complex, innovations in materials science promise even more robust solutions that can adapt to diverse environments.

Embracing these advancements means staying competitive in an ever-changing market landscape. The integration of Nu Van Tech’s 53 ft rubber seal not only signifies a commitment to quality but also positions businesses favorably against challenges they may face down the line. Adopting this technology could be your pathway toward sustainable growth and success in today’s dynamic industry climate.